Unleash the power of pristine acoustics without compromising on aesthetics with resonate™, OneFrame's cutting-edge sound-absorbing stretched fabric system. Crafted in New Zealand, this innovative solution is custom printed and shaped to seamlessly integrate into any space, providing an unparalleled auditory and visual experience.

Hear the Harmony, See the Elegance: Escape the tyranny of bulky furniture and unsightly acoustic panels. Introducing resonate™ - where acoustic control meets aesthetic refinement. Custom printed and expertly shaped, resonate™ allows you to control sound while maintaining the visual appeal of your space. Your visitors will revel in an environment that delights both the eyes and the ears.

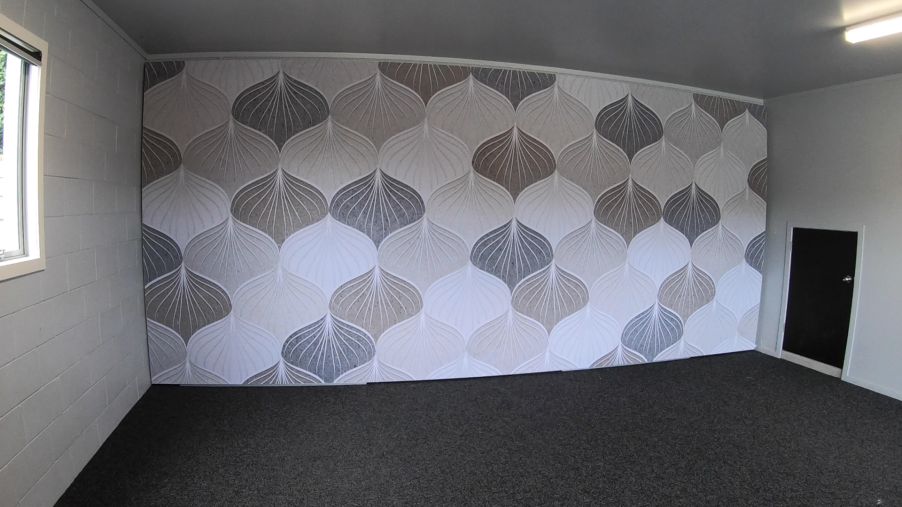

The Resonate™ Difference: Say goodbye to the limitations of traditional soundproofing solutions. With resonate™, you have the freedom to custom print any color or image onto our specially designed acoustic fabric. Shape it to fit your space perfectly, seamlessly integrating acoustic functionality into your design vision.

Innovative, Interchangeable, and Sustainable: resonate™ fabric skins are not only interchangeable, allowing you to refresh your space effortlessly, but also environmentally conscious. Crafted to be recyclable, resonate™ aligns with your commitment to sustainability. Our fabric spans up to an impressive 3 x 50 meters seamlessly, or even larger with a subtle seam, offering versatility that suits any spatial requirement.

Blend or Stand Out - Your Choice: Tailor your resonate™ system to match your unique style. Whether you prefer it to seamlessly blend into the existing ambiance or stand out as a focal point with dynamic graphics, branding, or messaging, the choice is yours. resonate™ adapts to your design sensibilities, ensuring your space is an expression of your creativity.

Why Choose resonate™?

Transform your space into a harmonious haven with resonate™. Revolutionize your acoustic design, control sound effortlessly, and let your space resonate with elegance and innovation. Elevate both the auditory and visual aspects of your environment with resonate™ by OneFrame.

*The above just texture examples, all production is done as a CMYK process from the supplied digital file. Physical proofing available to ensure we match outputs to your supplied specifications.

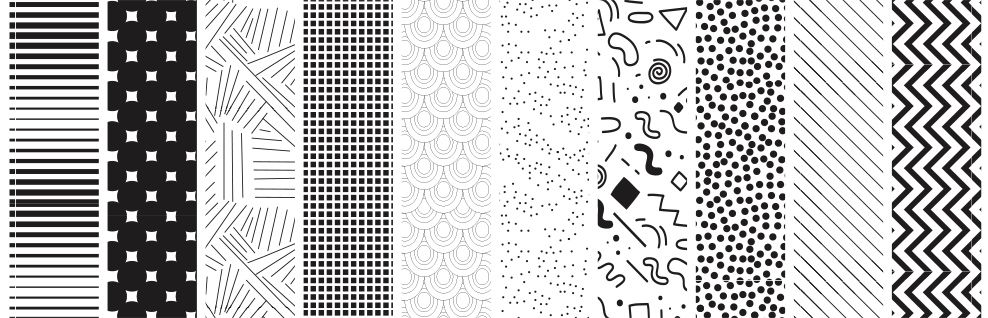

*The above are just pattern examples, all production is done as a CMYK process from the supplied digital file. Physical proofing available to ensure we match outputs to your supplied specifications.

*The above are just colour examples, all production is done as a CMYK process from the supplied digital file. Physical proofing available to ensure we match outputs to your supplied specifications.

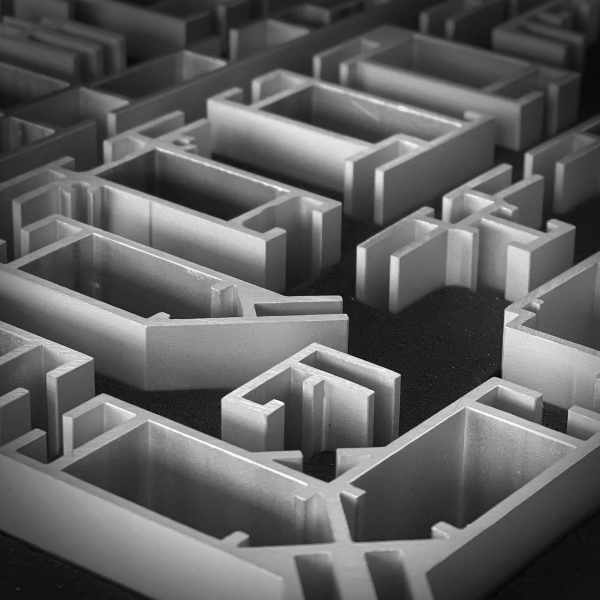

*The above are just image examples, all production is done as a CMYK process from the supplied digital file. Physical proofing available to ensure we match outputs to your supplied specifications.

The resonate™ fabric acoustic system is a custom, made to order sound-absorbing acoustic panel and stretch fabric system placed on walls or ceilings to control and reduce noise, eliminate slap echo, and control comb filtering in a room. The objective is to enhance the properties of sound by improving sound quality with this unique sound-absorbing customisable system.

With our leading expertise in fabric textile printing and finishing, you are able to have acoustic panels that appear as an image, pattern or solid colour of your choice, designed to enhance the interior design of your environment.

Where the resonate™ fabric acoustic system truly shines above anything else available in the market today is that you can achieve a maximum print width of 3200mm x 50 000mm long with no seam. For larger executions, we are able to use a near-invisible seam to manufacture and deliver oversized designs. Further to this graphics can also be removed to be washed and/or updated with a replacement graphic with our no-tools process.

The resonate™ fabric acoustic system also creates maximum return over an extended period so time as you are able to pay once for the custom-built frame and panels system along with its installation; then you or your staff can easily change out the textile printed graphic as required on-going.

Traditionally used to treat recording studios, churches, home theatres, restaurants, office work areas, corporate board rooms, hotel corridors and listening rooms. Acoustic noise control panels and surface coatings have become more popular and widespread as many recent commercial and residential designs give little consideration to noisy room acoustics with the increased popularity of large, polished surfaces and oversized glass windows.

The purpose of resonate™ fabric acoustic system is to reduce, but not entirely eliminate, resonance within the room. The resonate™ fabric acoustic system differs from bass traps in that they deal more with the mid and high frequencies in a room. It is also important to note that sound absorption is different from soundproofing, which is typically used to keep sound from escaping a room.

The dye-sublimation process is an eco-friendly process that uses no hard solvents, in contrast, it uses water-based organic inks with a vegetable/soy base ensuring there are no harmful chemicals being washed into our waterways. With a wide range of fabrics available, the most popular has seen our recycled yarn being the favoured choice. This is due to the corporate responsibility adopted by many of our customers to ensure they deliver using the best possible product whilst ensuring they do their part in looking after the planet.

The core range of the resonate™ fabric acoustic system aluminium profiles have been designed and extruded locally ensuring we stay true to our NZMADE delivery stance. With aluminium being the most recyclable metal available today, our system offers our customers a more sustainable option than traditional materials. We also have a range of composite profiles that have been developed for specialist applications where aluminium is not suited.

We’ve been working closely alongside some of the largest and most prolific acoustic substrate manufacturers worldwide to fine-tune our resonate™ fabric acoustic system. We believe that the added value of taking traditional aesthetical wall coverings, imagery or visual colour treatments and turning it into science delivers a product that will not only be aesthetically pleasing but delivers functional outcomes day in, day out.

Imagine being able to introduce a set percentage of the personalised resonate™ acoustic solution that has been made to functionally fit your space and aesthetically produced to align with your aesthetics/messaging all the while delivering a predetermined reduction of resonance within a room improving the overall sounds.

As with our entire product range, our customers have the option to engage our services at the end of life to ensure materials are repurposed, recycled or disposed of responsibly.

The resonate™ fabric acoustic system functionally outperforms any other comparable system available in the market today whilst offering unmatched customization and image colour reproduction to deliver the designed aesthetic. This paired with the environmentally-conscious materials selection and sustainability stance of the OneFrame brand makes us the ideal execution partner for your next project.

These innovative solutions not only contribute to a quieter and more comfortable environment but also offer aesthetic benefits that elevate the showroom’s design.